Selecting Purification Equipment to Comply with ISO8573-1:2010 Classifications

Simple Guidelines for The Selection of Purification Equipment

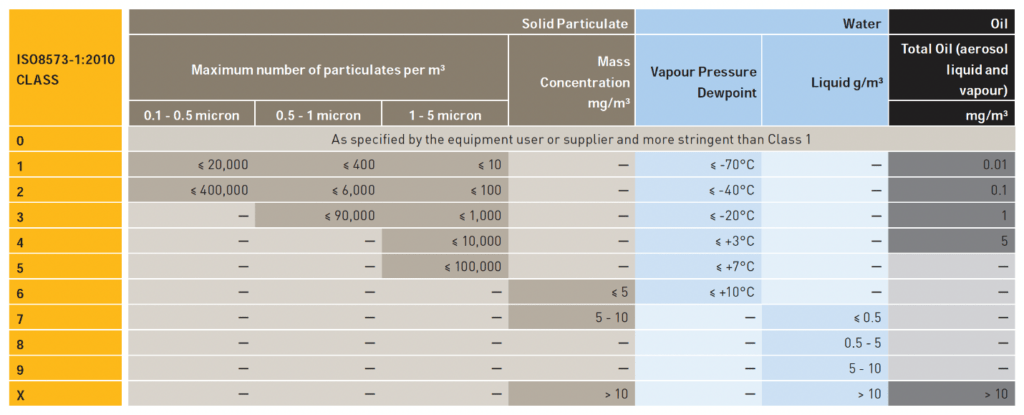

- Purification equipment is installed to provide air quality and you must first of all identify the quality of compressed air required for your system. Each usage point in the system may require a different quality of compressed air dependent upon the application. Using the quality classification’s shown in ISO8573-1 will assist your equipment supplier to quickly and easily select the correct purification equipment necessary for each part of the system.

- ISO8573-1:2010 is the latest edition of the standard. Ensure it is written in full when contacting suppliers. Specifying air quality as ISO8573-1, ISO8573-1:1991 or ISO8573-1:2001 refers to the previous editions of the standard and may result in a different quality of delivered compressed air.

- Ensure that the equipment under consideration will actually provide delivered air quality in accordance with the quality classifications you have selected from ISO8573-1:2010.

- When comparing coalescing filters, ensure that they have been tested in accordance with both the ISO 12500-1 and ISO 8573-4 standards.

- Ask for independent validation of product performance by a third party.

- For peace of mind, ensure the manufacturer provides a written guarantee of delivered air quality.

- Oil-free compressor installations require the same filtration considerations as oil lubricated compressor installations.

- ISO 12500-1 requires pressure losses for coalescing filters to be recorded when the element is saturated (wet dP). When considering the operational costs of coalescing filters, ensure the pressure loss stated in literature is the saturated pressure loss as initial or dry pressure loss is not representative of actual performance in a normally wet compressed air system.

- Look at the blockage characteristics of the filter. Just because it has a low starting dP, doesn’t mean it will remain low throughout the filter element’s lifetime. Energy costs should always be calculated based upon the blockage characteristics of the filter, not just initial saturated dp. Ask supplier for verification of blockage characteristics.

- Look at the total cost of ownership for purification equipment (purchase cost, operational costs and maintenance costs), a low initial purchase price, may look inviting, but may end up costing significantly more in terms of poor air quality and high operational costs.