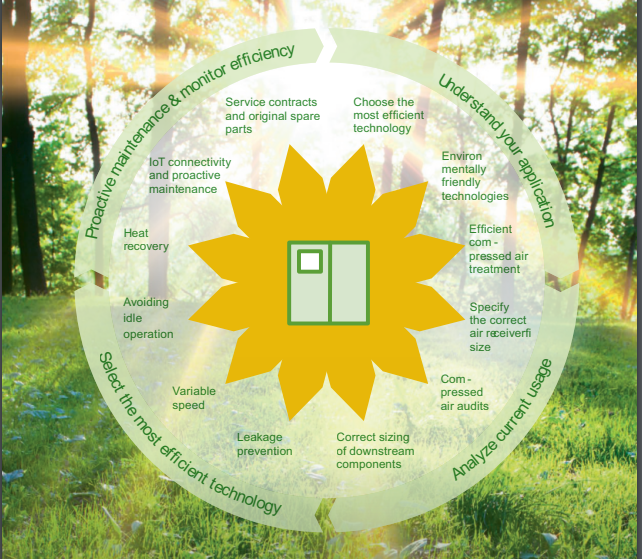

Use your compressed air technology as a sustainable energy source

The right technology for your application

For the right choice of compressor, you should not only know your compressed air requirements, but also parameters such as the operating pressure, the volume flow and the required compressed air quality according to ISO 8573-1:2010.

Efficient compressed air preparation

Because downstream equipment makes an important contribution to the quality and efficiency of the overall system, reducing environmental impact, there should be no compromise in the selection of these components. CompAir’s new compressed air treatment solutions are designed and manufactured in-house. You can be confident that their quality is controlled to the highest standards

Compressed air audits

When buying a new compressor or deciding to upgrade an existing system, an energy audit should be carried out. There is no easier way to find out about inefficiency!

Environmentally friendly technologies

Air compressors of the 100 % oil-free DH series have a highly efficient water purification system to generate particularly high quality injection water by means of reverse osmosis filtration. This makes lubrication, sealing and cooling easier. Another plus: the use of a permeate pump reduces water consumption to a minimum

Specify the correct air receiver size

The air receiver size has a direct impact on reliability and energy efficiency. Therefore, make sure the air reservoirs are correctly sized for the application. As a rule, the better the control system of the compressor is matched to demand (speedcontrolled systems), the smaller the compressed air receiver can be. Load/idle running-controlled systems require larger container volumes to reduce the switching operations of the compressor drives. This reduces wear and improves energy efficiency

Correct sizing of downstream components

When selecting filters, not only the validated separation efficiency (ISO12500-1) is important. The lowest possible flow resistance should also be achieved. It directly affects the energy requirements of your compressor. Also important: the line pressure. The higher the operating pressure, the bigger the impact on your electricity bill. Tip: It makes sense to optimise all components in the network to the lowest differential pressure. In the case of filter elements, the differential pressure increases with the service life; early replacement helps.

Leakage prevention

Leaks can be an extremely large waste of energy – for you and for the environment. It is best to regularly check the system for open shut-off valves. It is also worth looking at manual condensate valves and searching for faulty couplings, pipes or flanges helps to avoid leaks and thus indirectly reduce CO2 emissions.

Variable speed

If sustainability and environmental awareness are high on your agenda, variable speed drive compressors are the most efficient solution. Here you have a drive system that continuously adjusts the motor speed to the compressed air demand. In this way, your compressed air requirements can be individually tailored to.

Avoiding idle operation

If there is one thing that can really cost money and waste energy making a compressor environmentally unfriendly, it is off load running or idling, when a compressor runs but does not produce air. Check whether idling and the associated regular starting and stopping is really necessary. Better control or variable speed technology could help you reduce costs.

Heat recovery

Did you know that about 70 % to 94 % of the energy consumed by air compressors can be made usable with the help of heat recovery systems? This can help to reduce your running costs with less or in some cases no additional energy needing to be purchased. Helping to further reduce your company’s CO2 emissions and improve your CO2 footprint.