In the journey towards sustainability and net zero operations many global manufacturing organisations are turning away from the use and throw away mentality, this is especially true in the high-end spectrum as for example oil free compressed air. The procurement processes in organizations in practically all industries are turning away from simple mathematics of merely comparing the initial cost of equipment towards a thorough life cycle cost-type analysis. This is due to a few aspects:

- Production equipment initial cost is not the majority of their cost of operation

- Aging production equipment fleets (especially in Western economies) have a higher need for renewal compared to what the stock markets would prefer – production fleet investments are scarce

- Complex machines are costly to maintain and service businesses have become for many manufacturers the cash cow where most profits are made, and

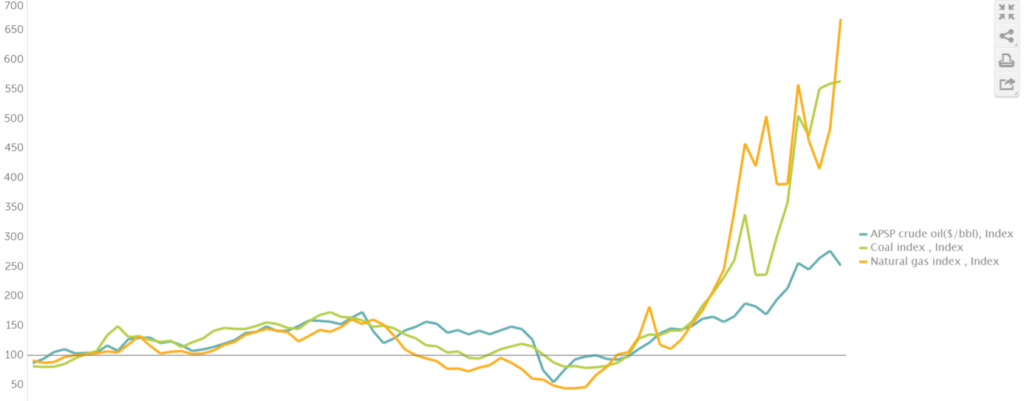

- Cost of energy to run the equipment has grown significantly since ‘the good ol’ days’.

Energy cost of compression accounts for 70-80% of the total cost of ownership

While the trend of purchase price accounting for a small portion of the life cycle cost seems to be true for most manufacturing equipment categories, the effect is very clear in compressor equipment. Depending on the type of equipment, the initial purchase cost can be as little as 10% of the cost of using the equipment over its life cycle. This is the case with compressors. First of all, depending on the technology used, the energy cost of compression accounts for 70 to 80% of the cost. And, with the constantly rising energy costs this proportion is naturally growing. Then, as legacy compressor technologies, especially in the oil-free air market, are very heavily maintenance-prone, the maintenance costs account for more than 10% of the cost of compressed air. The remainder is then the CAPEX part.

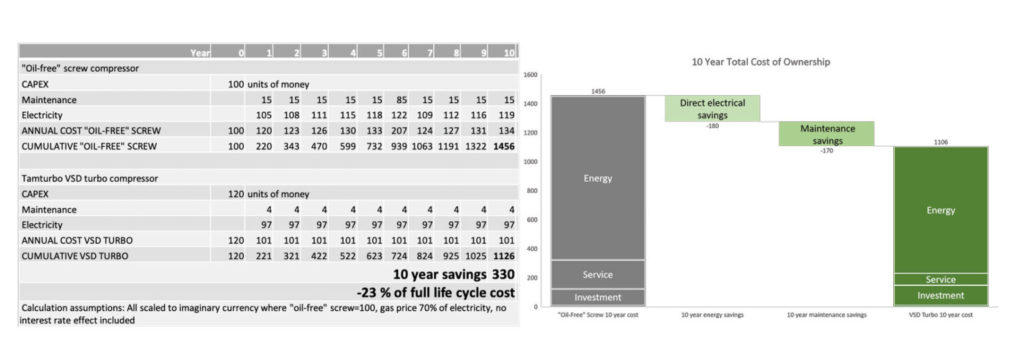

If we do a simplified life cycle cost calculation of an oil-free compressor, we might come to something like this (data from a real case, numbers scaled to imaginary currency so that purchase price of the “oil-free” screw compressor is set to 100 of this imaginary currency)

In addition to energy, the maintenance costs need to be considered when calculating the total cost of ownership

As can be seen from the example above, only X% of the total 20-year cost of compressed air is coming from the initial purchase. Please note that for simplicity, we have not used an interest rate to discount the future costs, though in reality that would be the case. The largest portion of the costs for each year are the electricity costs, which is annually similar to the purchase cost even with these 2020 energy prices. And a large difference can be seen in the maintenance cost difference between these two oil-free compression technologies. The 10 year maintenance cost for screw compressors is often more than double the cost of purchasing the unit. Due to its non-wearing technology a Tamturbo compressor requires very little maintenance, whereas screw compressors require more maintenance each year and a very costly air end overhaul every 4 to 7 years.

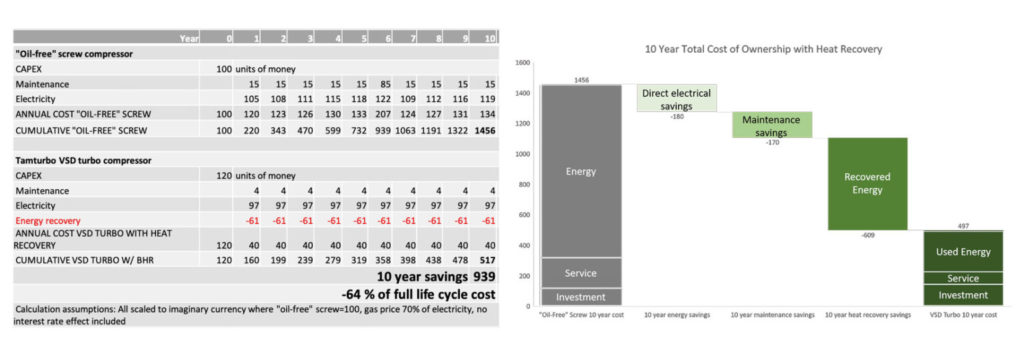

Reusing the heat energy plays an important role

If we really want to cut the life cycle cost of compressed air, we need to look at one more thing – reusing the heat energy that is created in the compression cycles. Legacy technologies don’t do this part well, which is logical as these technologies were developed even before the energy crisis of the 1970’s. A large portion of the excess energy for screw compressors is lost, even if there is a heat recovery option being used. When we take into account the energy that we can reuse, we can discount the annual cost of compression by the equivalent amount of primary energy (depending on the location this might be natural gas, coal, electricity). With 90% of the energy taken from the electrical grid the life cycle cost of compressed air becomes something totally different.

Why do we exclude “oil-free” screw energy recovery from the above calculation? The reason is simple: as the water cooling of screw compressors has been developed with only the unit cooling and lowest possible cost in mind it only delivers 50 to 60% of the energy in the water. And more importantly the “hot” water temperature can only reach around 55°C without seriously affecting the compression efficiency. And the temperature of the “hot” water fluctuates with the compressor load. This means that the “hot” water is often not worth the additional piping.

Tamturbo compressors recover the heat in 4 or even 5 phases, maximizing the delivered heat content, which is between 85% and 93% of the electrical energy taken from the grid. This means that with the Tamturbo standard heat recovery you get 38% more heat than from the “oil-free” screw compressors heat recovery. And the hot water temperature can be set to up to 90°C. We can also guarantee the hot water temperature stays constant regardless of the operating point of the compressor, which makes it directly usable in the production processes.

What does this all mean then?

It means that by changing compressors to a new technology will not only pay back very quickly, but it will start saving money immediately. In fact, you will save on average the 100 units each year, which is five (5) times the ‘extra’ you would have paid to purchase the better technology in the first place. And therefore, in 10 years you will have saved 50 times that amount by investing 20% more on the first year. Granted, this example doesn’t include the effect of interest rates, but even discounted that would still be in the ballpark of a ‘no-brainer’.

So, not only will your facility be more environmentally sustainable, you will have more money to spend on other critical things. A win-win for all those involved!